Clark Diesel Forklifts San Francisco

Diesel Forklifts Vs. Electric Forklifts

Forklifts could function one of two ways, either by internal combustion (IC) motor or by electric motor. Electric forklifts are suitable for indoor use and cost a lot less to operate. IC machines are suitable for outdoor application and are faster to refuel.

Electric Forklifts

For indoor applications, where air quality is a problem, the electric forklift is the suitable equipment you can use since it produces no exhaust. Electric forklifts are quiet and clean. They are 20% to 40% more expensive to buy than IC lifts, but the operating cost of electric models on a per hour basis is lower. The disadvantage is that batteries require 16 hours to charge and cool down, so the purchase of an extra set of batteries is recommended. Electric lifts are not limited for use indoors, but when used outdoors they must be used carefully.

Diesel Forklifts

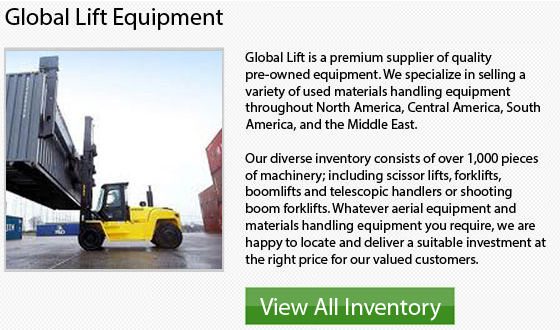

Internal Combustion forklifts are for outdoor use, and their carrying capacity is more than electric forklifts. If your fleet usually runs on one kind of fuel, it might be a good idea to buy an IC unit which uses the same type of fuel. They can function on propane, diesel or gas. Diesel is the least expensive. IC forklifts have the advantage of being less expensive to operate and easy to refuel; then again, their per-hour cost to operate is higher. The majority of IC models cannot be used indoors.

Other Kinds of Forklifts

Within warehouses where there are limited spaces, the narrow aisle electric forklift is most suitable. They are designed to pick up loads without having to position the lift facing the stacks. Rough terrain diesel forklifts have huge tires for running on hard surfaces.

- Terex Man Lifts San Francisco

Terex Manlift Specifications Terex is a Westport, Connecticut company which specializes in making in manufacturing construction machinery. Machines such as manlifts, boom lifts and aerial lifts. These types of machines are designed to facilitate access... More - Haulotte Rough Terrain Scissor Lifts San Francisco

Traditionally, industrial lifts have been used in production and manufacturing settings to raise and lower work things, people and materials. The scissor lift, also referred to as a table lift, is an industrial lift which... More - JLG Zoom Boom San Francisco

To handle all of your rough terrain difficulties, JLG offers the 400 Series and its fastest drive and lift speeds in its class which will ensure a boost in production. You would be able to... More - Omega Rough Terrain Forklifts San Francisco

MEGA Series - The MEGA Series is a powerful lift truck which is capable of covering a variety of applications. From steel and lumber and dealing with other kinds of heavy lifting as much as... More - Toyota Counterbalance Forklift San Francisco

For over 4 decades, Toyota has been among the leading suppliers of innovative lift trucks in the industry. Up to date, the business has sold more than 1 million forklifts. The company has earned a... More