Jungheinrich Dual Fuel Forklift San Francisco

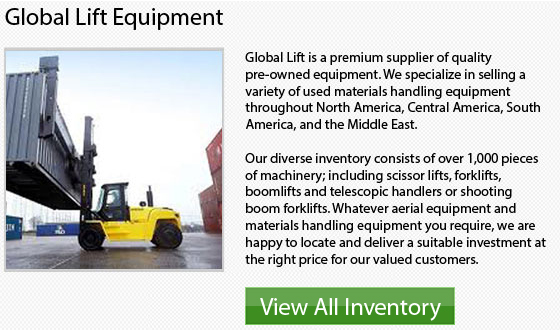

On construction sites all around the globe, forklifts, bobcats and bulldozers have become essential machines. Forklifts are versatile industrial machinery which are available in numerous sizes from fairly small to really big. They are designed to pick up loads and transport goods and materials within retail or warehouse settings. A lot are made to maneuver easily in tight, narrow areas. It takes both training and ability to correctly utilize a forklift.

Forklifts could be found in nearly all warehouses since they are essential pieces of machines for effective materials handling. They are usually used inside warehouses and stockrooms to place and retrieve huge or heavy things that are stored up high. They are important for production in work settings where there is a small place to store a large range of stock. These kinds of trucks are manufactured to move large pallets around in factories.

Lift truck operators within North America are required by law to go through a training and certification course. This training can be done on the jobsite or in a schoolroom or lecture style setting. Normally training is delivered at the workplace. Training and accreditation usually means a pay raise for the individual obtaining new skills. Forklifts have standard operating procedures, that makes it easy to get trained on various kinds of lift trucks.

Smaller machinery accommodate one operator inside the cab and can maneuver in small, tight areas. The bigger equipment are huge and can lift automobiles, trucks or other heavy pieces of machines. Lift trucks could lift thousands of pounds easily.

Construction companies usually give salary raises to workers who undergo the training. Employers will usually send an employee to classes to train on a big piece of machinery. Willingness to train on a bull dozer, a lift truck or a bobcat will certainly pay off.

- Terex Man Lifts San Francisco

Terex Manlift Specifications Terex is a Westport, Connecticut company which specializes in making in manufacturing construction machinery. Machines such as manlifts, boom lifts and aerial lifts. These types of machines are designed to facilitate access... More - Haulotte Rough Terrain Scissor Lifts San Francisco

Traditionally, industrial lifts have been used in production and manufacturing settings to raise and lower work things, people and materials. The scissor lift, also referred to as a table lift, is an industrial lift which... More - JLG Zoom Boom San Francisco

To handle all of your rough terrain difficulties, JLG offers the 400 Series and its fastest drive and lift speeds in its class which will ensure a boost in production. You would be able to... More - Omega Rough Terrain Forklifts San Francisco

MEGA Series - The MEGA Series is a powerful lift truck which is capable of covering a variety of applications. From steel and lumber and dealing with other kinds of heavy lifting as much as... More - Toyota Counterbalance Forklift San Francisco

For over 4 decades, Toyota has been among the leading suppliers of innovative lift trucks in the industry. Up to date, the business has sold more than 1 million forklifts. The company has earned a... More