Skyjack Manlifts San Francisco

Skyjack Safety

A scissor lift is a particular type of industrial machine that is utilized for "positioning personnel, their equipment and their tools," based on Skyjack. Anybody who is getting ready to use this kind of machinery must familiarize themselves with the suggested operational and safety procedures recommended by the manufacturer in order to stay safe prior to attempting to utilize this machinery. It can be devastating to the operator themselves and any bystanders resulting in severe injuries if the safety procedures are not followed.

Area

In the best case scenario, the scissor lift will be operated on totally level ground. Before driving a scissor lift over a particular terrain, the area has to be checked and cleared of any debris. To be able to lessen the risks of the scissor lift tipping over and probably causing the operator to fall from his seat. It is recommended to avoid holes or steep grades while operating. Bystanders should also remain aware and stay clear of the operating scissor lift so as to make sure that they do not get run over.

Inspection

The user needs to thoroughly inspect all integral parts of the device before trying to utilize a scissor lift. A functional test done while the lift is retracted allows the operator to see if all parts are correctly functioning before the task is initiated. It is recommended to complete a daily check on this machine prior to starting the shift and some places even want an inspection to occur at the end of the shift too. Different companies have various policies in place to maintain safety.

Part of the inspection needs to be inspecting the tires. These components obviously add to the movability of the scissor lift and also provide the machinery with a solid foundation. A faulty or worn tire could blow and throw the operator from their place on top of scissor lift.

- Terex Man Lifts San Francisco

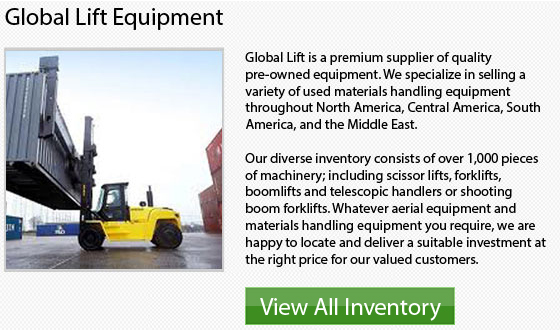

Terex Manlift Specifications Terex is a Westport, Connecticut company which specializes in making in manufacturing construction machinery. Machines such as manlifts, boom lifts and aerial lifts. These types of machines are designed to facilitate access... More - Haulotte Rough Terrain Scissor Lifts San Francisco

Traditionally, industrial lifts have been used in production and manufacturing settings to raise and lower work things, people and materials. The scissor lift, also referred to as a table lift, is an industrial lift which... More - JLG Zoom Boom San Francisco

To handle all of your rough terrain difficulties, JLG offers the 400 Series and its fastest drive and lift speeds in its class which will ensure a boost in production. You would be able to... More - Omega Rough Terrain Forklifts San Francisco

MEGA Series - The MEGA Series is a powerful lift truck which is capable of covering a variety of applications. From steel and lumber and dealing with other kinds of heavy lifting as much as... More - Toyota Counterbalance Forklift San Francisco

For over 4 decades, Toyota has been among the leading suppliers of innovative lift trucks in the industry. Up to date, the business has sold more than 1 million forklifts. The company has earned a... More