Potain Self Erect Cranes San Francisco

For large building construction projects, tower cranes are used rather frequently. These machinery are quite essential for heavy lifting as well as positioning supplies and equipment. Tower cranes offer a unique design which provides many benefits over more conventional cranes. These benefits comprise: quiet electrical operation, higher vertical lift, increased capacities, and reduced space requirements.

Hammerhead Crane

The hammerhead crane is usually associated with a tower crane. The long horizontal jib is connected to a vertical tower, in this case. One end of the jib extends horizontally over the worksite and the other end of the jib acts as a counterweight. There is a trolley on the hammerhead crane. This trolley has the lifting cable and can travel along the length of the jib. The tower crane is capable of operating anywhere in the jib's radius.

Self-Erecting Tower Cranes

Self-erecting cranes are often assembled on site with the assistance of a different crane. This provides a huge benefit in setup time and really saves time in equipment costs as well. Self-erecting cranes are usually remote-controlled from the ground, though there are some models that have an operator cab built onto the jib.

Self-erecting cranes are normally freestanding and this allows them the opportunity to be able to be moved around. There are several models that have a telescoping tower which enables the crane to work at various heights without the need to reconfigure the tower.

Luffing Jib Tower Crane

Nearly all urban work settings do not have enough clearance or space for the jib to rotate freely without existing buildings blocking its movement. A luffing jib tower crane is great for such tight spaces. The majority of tower cranes have a fixed horizontal jib. The operator could lower or raise a luffing jib in order to enable the crane to swing in a reduced radius.

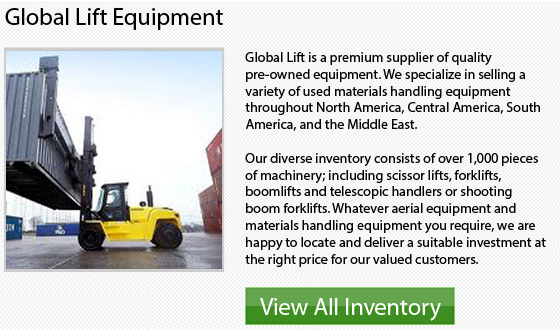

- Caterpillar 4 Wheel Drive Forklifts San Francisco

Side shifter: Side shifters are attachments which allow operators to position the attachment arms laterally for more effective load placement. Forklift fork Positioner: A kind of hydraulic attachment which helps position the forks separately or... More - TCM Outdoor Forklifts San Francisco

There exists such a huge range of different kinds of lift trucks on the market. Among the initial factors you need to make when you are planning to purchase one is whether or not the... More - JLG Zoom Boom San Francisco

To handle all of your rough terrain difficulties, JLG offers the 400 Series and its fastest drive and lift speeds in its class which will ensure a boost in production. You would be able to... More - Hyundai Warehouse Forklifts San Francisco

Warehouse Forklift Types Forklifts are multi-purpose equipment that could be used indoors and outdoors. They can function on rough terrain and are a common piece of industrial equipment found in warehouses or on construction sites.... More - Toyota Counterbalance Forklift San Francisco

For over 4 decades, Toyota has been among the leading suppliers of innovative lift trucks in the industry. Up to date, the business has sold more than 1 million forklifts. The company has earned a... More